Acoustic screen installation at a chemical manufacturing facility in Gloucestershire.

Application Details:

A chemical manufacturing facility had experienced high levels of noise from fixed mechanical plant in its factory, which had caused disruption to nearby workers.

SUPPLY SCOPE:

Design, supply and installation of an assortment of high-specification acoustic solutions, including acoustic attenuators, an acoustic screen and acoustic door, to reduce noise and employee risk.

ACOUSTIC PERFORMANCE:

The bespoke acoustic screen and acoustic louvres were designed to deliver an estimated nominal 5-10dB noise reduction.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

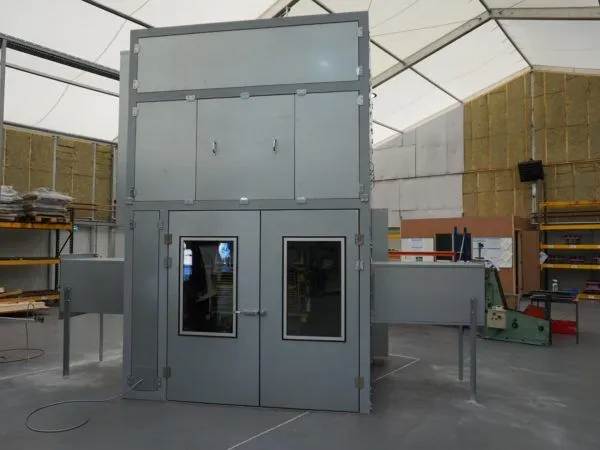

Acoustic attenuators, acoustic plant screen and acoustic door installation at a flooring manufacturing site in Derbyshire.

Application Details:

Environmental noise from a blower room and a new chiller was causing problems at a flooring manufacturing facility in Derbyshire. The blower room was producing low frequency noise, which needed to be addressed before the plant could be run for a proposed 24-hours a day period.

SUPPLY SCOPE:

Design, supply and installation of an assortment of high-specification acoustic solutions, including acoustic attenuators, an acoustic screen and acoustic door, to reduce noise and employee risk.

PRODUCT SELECTION AND PERFORMANCE:

In order to effectively combat noise, a selection of acoustic solutions were designed and installed. Due to the high level of noise reduction required, acoustic attenuators, complete with weather louvres, were designed to extend out of the wall of the blower room.

To further reduce noise, the existing wooden plant room door was removed and replaced with a high-performance steel acoustic door. Whilst an acoustic screen was also installed around the chiller, further mitigating noise and blocking the direct line of sight to local residents.

ACOUSTIC PERFORMANCE:

The acoustic attenuators were designed to deliver an estimated nominal noise reduction of 20dBA, whilst the acoustic screen was developed to produce a nominal 5-10dBA reduction. Such a reduction will enable the flooring manufacturer to operate plant for a 24-hour period.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Acoustic enclosure installation at an automotive manufacturing facility.

Application Details:

An automotive manufacturing facility had experienced high levels of noise from metal presses in their plant. Noise emissions from the presses was breaking out of the building and causing disturbance to nearby residential properties.

SUPPLY SCOPE:

In order to effectively mitigate noise in the facility and limit the environmental noise breakout to surrounding residents, Wakefield Acoustics designed, manufactured and installed large acoustic enclosures to house the metal presses.

PRODUCT SELECTION AND PERFORMANCE:

Wakefield Acoustics designed and fabricated the acoustic enclosures with forced ventilation systems. Each enclosure also integrated inlet and outlet acoustically lined ‘tunnel’ sections for material conveyors.

ACOUSTIC PERFORMANCE:

The bespoke acoustic enclosures were designed to deliver a nominal 20dB-25dB reduction.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Application Details:

Centrifuge Acoustic Enclosure

SUPPLY SCOPE:

Two acoustic enclosures supplied to house centrifuge machines mounted on a raised platform. The units were supplied with a high-specification 2-coat polyester powder paint finish to provide protection against corrosion of the panels and framework.

A sliding access door is incorporated at the end of the enclosure for access to pipework and valves. Additional means of access is also provided via hinged slide wall acoustic plant screens.

An integrated ventilation system was built into the enclosures, with inlet air drawn across the large drive motor, and warm air extracted by means of a cased axial fan mounted into the side wall of the housing. The ventilation system was designed with appropriate rectangular splitter attenuators in order that the integrity of the acoustic panelling system was not compromised.

PRODUCT SELECTION AND PERFORMANCE:

The overall enclosure system was designed to reduce the omitted noise levels by 12/15 dB(A).

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Application Details:

Blower Enclosures and Inlet systems for waste water aeration

SUPPLY SCOPE:

A series of acoustic packages for large blowers including ventilated acoustic enclosures to reduce breakout noise from blower casing and inlet filter silencers.

The enclosures were designed with integrated lockable access doors for maintenance and lift off roof panels for plant removal. The items supplied were complete with paint finish to WIMES Table 2 and a ventilation system was designed and supplied.

PRODUCT SELECTION AND PERFORMANCE:

The equipment was designed to reduce noise to 80dB(A) at 1m

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Application Details:

Acoustic treatment for four blower enclosures at a waste water treatment plant.

SUPPLY SCOPE:

Wakefield Acoustics designed and manufactured four bespoke acoustic enclosures for the plant. Each includes a forced ventilation system, inlet filter silencers with facing acoustic louvres, as well as discharge and blow off silencers.

PRODUCT SELECTION AND PERFORMANCE:

Our expert team factory assembled the acoustic enclosures to measure 6.2 long x 3m high x 3 m wide. Furthermore, each was manufactured to include lift off roofs for major maintenance activities.

ACOUSTIC PERFORMANCE:

Designed to reduce noise in order to meet a 74dBA specification.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

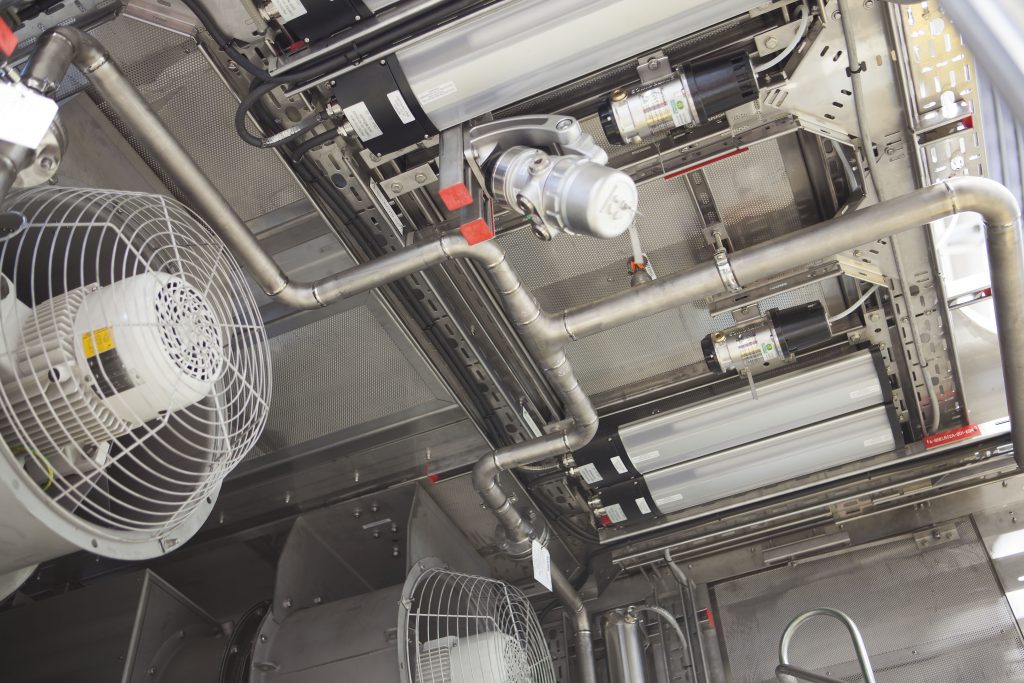

Application Details:

Longstanding environmental noise issues from pump sets and motors and the associated pipework were causing problems for nearby residents at a water treatment site in Kent.

SUPPLY SCOPE:

Design, supply and installation of a close-fitting acoustic enclosure around the pumpsets and motors in the pump house. The enclosure included integrated ventilation fans and inlet ventilation attenuation, to reduce environmental noise and the associated impact on nearby residents.

PRODUCT SELECTION AND PERFORMANCE:

In order to effectively mitigate noise, the acoustic enclosure was designed to fit around existing pipework and obstructions in a congested area.

ACOUSTIC PERFORMANCE:

The acoustic enclosure was designed to deliver an estimated nominal noise reduction of 15dBA.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Application Details:

Acoustic Enclosures for Oil Export, Oil Booster, Main Water Injection, Produced Water Booster and Sea Water Booster Pump packages

SUPPLY SCOPE:

Series of 316 grade stainless steel acoustic enclosures supplied for 17 no specialised pump sets. Each unit was designed with a fully integrated, Atex rated ventilation system. The enclosure units were pre-assembled within our factory prior to being fitted out with fire and gas detection systems, a number also including titanium sprinkler pipework systems. All housings were modelled using Finite Element Analysis to ensure compliance with the project blast load requirements. The overall dimensions of the larger enclosure packages were approximately 9m long x 3.5m wide x 6.5m high. Given the scale of the enclosures on site the product design required that the product was manufactured in a sectional modular form for transportation. Final installation work was undertaken by our installation team prior to factory acceptance testing.

PRODUCT SELECTION AND PERFORMANCE:

The enclosures were designed with material panel thickness to reduce the package noise levels from typically 90-95dB(A) to 72dB(A) at 1m

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Application Details:

Acoustic Enclosures for vertical pump units.

SUPPLY SCOPE:

2 off acoustic enclosures manufactured from 316L stainless steel complete with an ATEX rated warm air extraction system and acoustic louvres and acoustic attenuators.

The enclosure framework and panelling was designed to withstand a blast load of 0.2bar following a full dynamic transient analysis undertaken as part of our contract works. The enclosures were fitted with an integrated fire and gas detection system.

Due to spatial limitations on site these close fitting enclosures were designed with a large number of removable/hinged access panels and polycarbonate viewing windows.

PRODUCT SELECTION AND PERFORMANCE:

The enclosures were designed to reduce transmitted noise to 80dB(A) at 1m

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

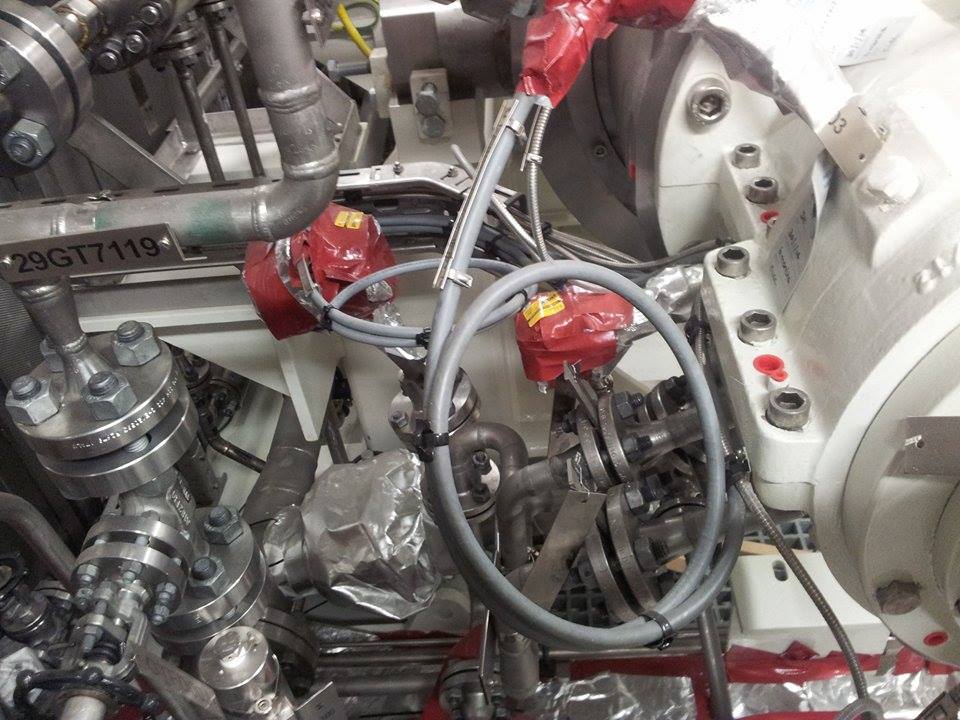

Mariner Oil Field, off shore Norway

Application Details:

Acoustic Enclosures for Water and Diluent Injection Pump Packages

SUPPLY SCOPE:

Series of 316 grade stainless steel acoustic enclosures supplied for 6 no specialised pump sets.

The enclosure units were pre-assembled within our factory prior to being fitted out with fire and gas detection systems and titanium water deluge piping.

The overall dimensions of the larger enclosure packages were approximately 9.0m x 4.1m x 4.3 m. Given the scale of the enclosures on site the product design required that the product was manufactured in a sectional modular form for transportation . Final commissioning and installation were undertaken by our on site team prior to factory acceptance testing.

PRODUCT SELECTION AND PERFORMANCE:

The enclosures were designed with material panel thickness to reduce the untreated noise levels from typically 95-100dB(A) at 1 metre.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.