Acoustic enclosures installation at an offshore oil field.

Application Details:

Excessive noise from high pressure water pumps was causing problems at an offshore oil field.

SUPPLY SCOPE:

Design, manufacture, supply and installation of a series of bespoke high specification acoustic enclosures to mitigate excessive noise levels, in line with the UK’s Control of Noise at Work Regulations 2005.

PRODUCT SELECTION AND PERFORMANCE:

In order to effectively mitigate noise, a selection of bespoke 316 stainless steel acoustic enclosures were designed and installed on-site. Each enclosure included integrated acoustic louvres for ventilation of the equipment, while maintenance access was granted by folded framework and a high number of access doors. Vision panels and windows were also included in the design.

ACOUSTIC PERFORMANCE:

The high-specification acoustic containers were designed to deliver a nominal noise reduction in line with the client’s requirements.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Application Details:

Acoustic screens for air conditioning and ventilation plant

SUPPLY SCOPE:

Total of 3 no. roof-mounted acoustic screens for the reduction of noise emissions to comply with planning requirements. The screens were supplied complete with supporting steelwork, designed and fabricated by Wakefield Acoustics.

Special Requirements

The screens incorporated personal access doors for plant maintenance. In order to assist with installation due to access issues, the screens were fabricated in large pre-assembled sections, complete with steelwork supports, to aid installation on site.

PRODUCT SELECTION AND PERFORMANCE

The acoustic panels were designed to offer a direct transmission loss of 25dBA.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Application Details:

Acoustic louvres for roof-mounted plant equipment in Covent Garden, London.

SUPPLY SCOPE:

Design, supply and installation of approx. 50m² of acoustic louvres to reduce plant noise at the surrounding buildings to levels specified by the acoustic consultant.

Special Requirements

Due to both acoustic and aesthetic requirements, two types of louvres were required for the project. To meet more stringent noise requirements, bespoke designed 300mm deep chevron acoustic louvres (Type WA-ACL-300DB) were installed, preventing line-of sight through to the plant equipment from below.

A bespoke design single bank inverted acoustic louvre (200mm deep), with an additional weather guard to minimise water ingress, was installed on the face of the surround. Due to a less stringent noise specification on this face of the surround, these louvres were designed to again eliminate line-of-sight through to the plant equipment from below, while minimising the depth of the louvre and the cost for the customer.

PRODUCT SELECTION AND PERFORMANCE

The acoustic louvres were designed to offer significant reductions in noise transmissions.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Acoustic screen installation at Trinity Leeds shopping centre

Application Details:

Acoustic screen installation at Trinity Leeds shopping centre in the heart of the city.

SUPPLY SCOPE:

Design, manufacture, supply and installation of a 35m roof mounted acoustic screen, located to a height 3m above the roof level at Leeds Trinity Shopping Centre, to reduce HVAC plant noise.

Special Requirements

In order to effectively mitigate noise from HVAC plant equipment, a bespoke designed acoustic screen was supplied and installed on the roof of the shopping centre. The high specification screen was supplied with structural support steelwork and access doors. While a polyester powder paint finish was applied to the acoustic panels.

ACOUSTIC PERFORMANCE:

The acoustic screen was designed to offer significant reductions in noise transmissions.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Acoustic louvres and acoustic louvred doors installation at a residential development in London.

Application Details:

Environmental noise issues from air conditioning plant equipment at a residential development in London following a BS4142 assessment.

SUPPLY SCOPE:

To mitigate environmental noise levels, and meet performance levels specified by the consultant following a BS4142 assessment, we installed acoustic louvres, acoustic louvred doors and matching flash trims to the facades of the plant area.

Product Selection and Performances:

The acoustic louvres were specially designed to meet performance levels specified by the consultant following the BS4142 assessment.

ACOUSTIC PERFORMANCE:

The acoustic louvred door and over panel were designed to offer significant reductions in noise transmissions, in line with the consultant’s requirements.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Application Details:

Acoustic louvred door and over panel at a luxury residential development in London.

Environmental noise from air conditioning plant equipment at a luxury residential development. The plant was producing excessive noise that was impacting on nearby areas around the development.

SUPPLY SCOPE:

Design, manufacture, supply and installation of a high-specification acoustic louvred door and over panel to reduce noise from air conditioning plant equipment, and the associated environmental noise impact on nearby areas. The installation was also necessary in order to permit airflow to the plant.

Product Selection and Performances:

To efficiently attenuate noise emissions and meet the consultant’s requirements, the bespoke acoustic louvred door and over panel were fitted around the existing air conditioning plant. The integrated louvred door permitted access for plant maintenance.

ACOUSTIC PERFORMANCE:

The acoustic louvred door and over panel were designed to offer significant reductions in noise transmissions, in line with the consultant’s requirements.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Application Details:

Oxidiser blowers, Malaysia

SUPPLY SCOPE:

Skid mounted enclosures for a total of 6 no. rotary lobe blowers on an oxidizer plant. The acoustic enclosures were designed as a 1-piece drop over unit, supplied complete with large hinged panels for maintenance access, and integrated ventilation system comprising of a run and standby fan arrangement. Fans supplied to Atex zone 2 rating. Enclosures fitted with removable a coupling guard cover.

Product Selection and Performances:

Enclosures and ventilation attenuation was selected to reduce noise levels to 85dBA at 1m per package.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Application Details:

Wasit Gas Plant, Saudi Arabia

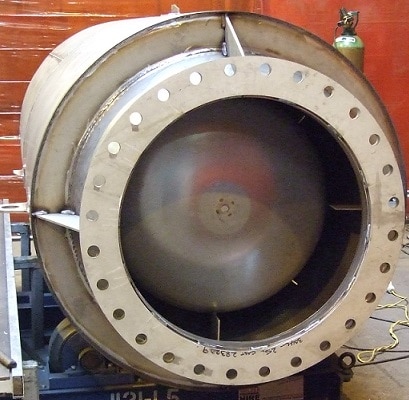

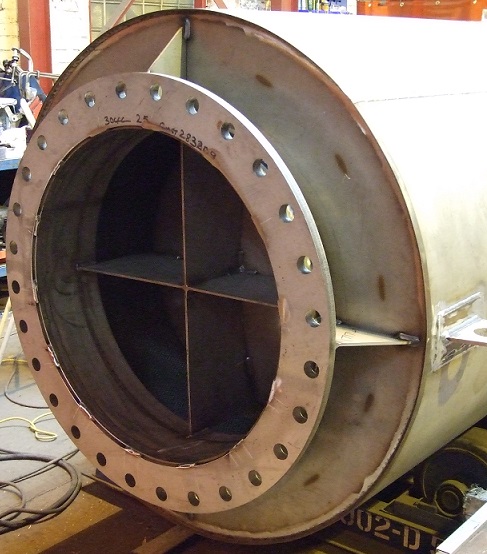

Silencers for centrifugal blowers

SUPPLY SCOPE:

Fully welded high pressure silencers manufactured from 304 stainless steel and fitted with ASME 16.47 flat faced flanges complete with earthing point.

To boost acoustic performance the units were fitted with a concentric pod and were selected to handle an air volume of 38,000m3/hr airflow @ 126 degree C.

Product Selection and Performances:

Products were designed to provide a minimum noise reduction of 15dB(A)

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Application Details:

Design, supply and installation of acoustic enclosures and ventilation systems for gas engine on hospital site.

SUPPLY SCOPE:

Site-assembled galvanised steel acoustic enclosure with demountable side wall section. Enclosure installed with 2 no. 500kg lifting beams, tested and certified on site. Ventilation system designed to connect to existing external weather louvres in boiler house. Ventilation system comprised of 2 no. axial flow fans, motorised dampers, inlet filters and louvres along with attenuation and ductwork systems.

Product Selection and Performances:

Enclosure and attenuation designed to reduce noise levels to 70dBA at 1m based upon untreated levels of 100-105dBA.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.

Application Details:

Design, supply and installation of large acoustic enclosures and ventilation systems for 2 no. 2MW engines

SUPPLY SCOPE:

Site-assembled acoustic enclosures with demountable front wall sections for major maintenance activities. Enclosures installed with 3 no. 500kg lifting beams, tested and certified on site. Ventilation system installed to each enclosure, comprising of 3 no. axial flow fans, motorised dampers, inlet filters and louvres along with appropriate attenuation and ductwork systems.

Product Selection and Performances:

Enclosure internal walls designed to reduce noise levels to <75dBA at 1m to reduce noise experienced by plant operators. External portions of enclosure and ventilation attenuators designed to achieve 39dBA at 30m from installation.

Get In Touch

Engineering excellence in designing, manufacturing and installing industrial, commercial and environmental noise control products and systems.